By Laser 1 Technologies

We Follow the Trends – You Reap the Benefits

It’s an excellent time to be in manufacturing. Just when you thought that technological breakthroughs couldn’t get any better – bam – something far superior comes along.

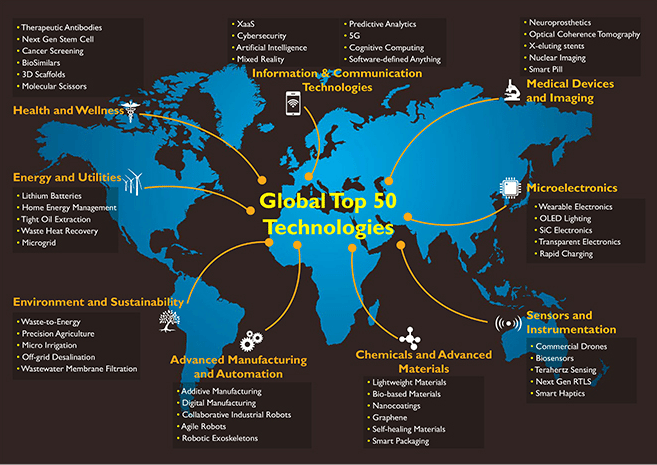

Growth consultants, Frost & Sullivan, recently released the Top 50 Emerging Technologies that are expected to “pack maximum potential to fuel global innovation; spawn innovative products and services; and drive commercial growth.”

50 technological changes that will “transform the world.” Goodness. The number is a bit overwhelming, so we’ll start with what I consider promising technologies that impact and create change in the world of manufacturing.

Wearable Technology

Wearables fall into that “so cool” category. Largely, use of wearables has focused on wrist accessories, glasses, and clothing for automation of data collection. But have you ever thought about using your skin as a display in communicating with other technologies?

Check out this recent Manufacturing Minute about using your palm as a touchscreen.

Additive Manufacturing

Additive manufacturing uses 3D modeling software technology to build objects by adding layer upon layer of materials [e.g. plastic, metal, concrete, etc.] This type of production encompasses many technologies including rapid prototyping, direct digital manufacturing, and additive fabrication. Additive manufacturing opens the doors to creative innovation and customization or repair of products.

By 2019, additive manufacturing is expected to reach $20.4 billion. This tremendous growth will lead to inventive changes that will further influence the manufacturing industry. “Through the 3D scanning of items, manufacturers can streamline the design and manufacturing process to rapidly create microscopically identical parts from nearly any location.”

Additive manufacturing is changing the landscape of present-day production.

“Okay, who ordered the customized spleen?”

Robots

According to the International Federation of Robotics, “In 2014, robot sales increased by 29% to 229,261 units, by far the highest level ever recorded for one year” with the primary drivers of growth being automotive parts suppliers and electrical and electronics industries. “China has considerably expanded its leading position as the biggest market with a share of 25% of the total supply in 2014.”

Currently, it’s estimated that 59% of manufacturers are using robotic technology. Robots have evolved and taken on automated roles in packaging, testing, and inspecting, as well as intricate and precise work unattainable by humans.

These technological trends inspire, challenge, and motivate us.

Yes, wearable technology, additive manufacturing, and robots have been around for a long time. The concept isn’t new. What is revolutionary – the dramatic changes made in each area.

As your strategic partner, we are always researching various manufacturing options and looking for ways to help reduce costs and minimize production time. The staff at Laser 1 will help you to determine which emerging technological advancement is the most cost-effective solution for the manufacturing of your product. Give us a call today at (651) 451-9397.