By Laser 1 Technologies

3D Printing – From Hype to Game Changer

In December 2014, U.S. News and World Report informed its followers that one of the fifteen sectors to watch in 2015 included growth in 3D printing. The forecast – a “skyrocketing number of companies” would “provide additive manufacturing as their primary service to other businesses.”

In fact, along with medical marijuana and telemedicine, 3D printing ranked among the top emerging 2015 industries. Kristina Zucchi, CFA, reported in Investopedia that, “A recent study by PricewaterhouseCoopers concluded that 67 percent of surveyed manufacturers are currently implementing 3D printing and an additional 25 percent have future adoption plans.” She went on to report that technology research firm Canalys estimated “the global market for 3D printing services and materials was $3.8 billion in 2014 and will be $16.2 billion by 2018, resulting in a compound annual growth rate of 45.7 percent.” Based on IBISWorld estimates, the United States “has about a 47 percent market share with a projected compound annual growth rate of 15.7 percent in the next three years.”

There’s only one word to describe this phenomenon, “incredible.”

In such a short time span, few areas of technology have seen as much development as that of 3D printing. This emerging technology is a game changer in the field of manufacturing.

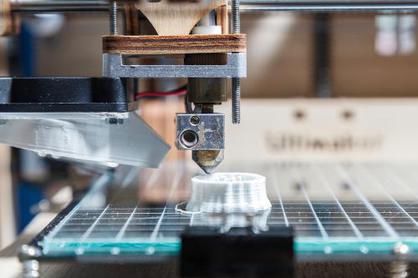

What is 3D printing? The most simplistic of explanations is the production of physical objects as specified by computer software containing a virtual 3D model of that object. These 3D printers incrementally deposit layer upon layers of substrate (metals, plastic, wood, etc.) to create an end product.

As with any emerging technology, initial pricing can be prohibitive to many businesses. The good news, 3D printer’s costs have been decreasing over the past few years. With increased competition and technological progress for manufacturers of 3D products, we’re bound to see prices drop even more rapidly.

There’s a 3D printing revolution around the bend.

As reported in Investopedia, “International Data Corporation (IDC) predicted that by the year 2020, more than 10% of all consumer products will be available through produce on demand via 3D printing – in home or through companies offering such services.” Adam Hayes, CFS, went on to report that, “the longer term implications of a 3D printing economy are certainly disruptive if they happen on a large enough scale. If even 10%-20% of all consumer goods can be manufactured on demand and customized to the end-user’s preferences, it would transform the modern factory and manufacturing process. Inventories would no longer need to be stocked, as goods would be produced only as needed, reducing the demand for warehouse space and inventory management systems. Many of these items would initially be simple, solid items such as toys, flatware, jewelry, and other trinkets, currently made by China or other exporters whose services would no longer be needed.”

No longer need to manufacture in China? You bet!

Reshoring, it’s all about bringing the manufacturing of products back to the United States. 3D printing has already started to change the way goods are manufactured and the operations of a business.

We are simply ecstatic about this emerging technology.

What’s even more exciting, Rolls-Royce, maker of Trent XWB-84 (only the most efficient large aero engine) will soon be coming out with the Trent XWB-97. This will be the highest thrust engine ever certified – with components produced by 3D printing. Simon Burr, the Chief Operating Officer, noted that two benefits to 3D printing are the design freedom and reduction of lead time in engine development. In 2016, Airbus is due to fly the first A350-1000 using an engine built with 3D technology.

As your strategic manufacturing partner, we are always researching various manufacturing options and looking for ways to help reduce costs and minimize production time. Laser 1 will help you to determine if 3D printing is the most cost-effective solution for the manufacturing of your product. Give us a call today at (651) 451-9397.